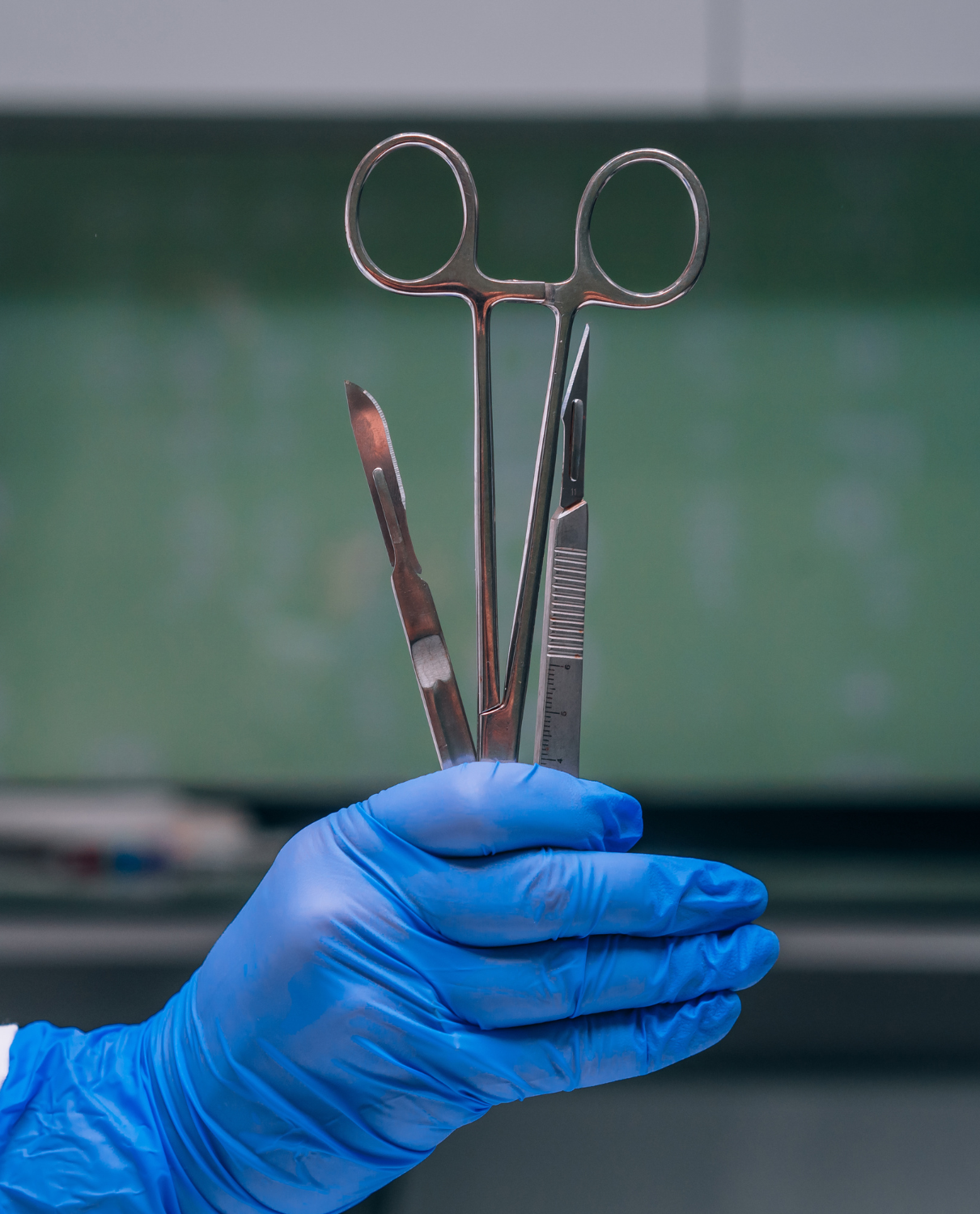

At Dr. Spaul Enterprises, we manufacture and supply a comprehensive range of surgical and medical instruments engineered for accuracy, safety, and reliability.

In the operating room, every millimeter matters. A slight deviation in sharpness, alignment, or pressure can impact outcomes. That’s why precision isn’t just a standard — it’s science. At Dr. Spaul Enterprises Pvt. Limited, our instruments are engineered at the intersection of metallurgy, biomechanics, and surgical ergonomics.

We don’t just make instruments — we craft extensions of a surgeon’s skill, designed to perform flawlessly under pressure, time after time.

⚙️ The Science Behind Surgical Precision

Reliability in surgical instruments doesn’t happen by chance. It’s the outcome of meticulous design, rigorous testing, and continuous innovation. Here’s how science defines precision at every stage of our process:

Material Integrity

Every instrument begins with certified surgical-grade stainless steel or titanium. These materials resist corrosion, maintain edge retention, and withstand repeated sterilization cycles — essential for reliability in surgical environments.

Ergonomic Engineering

We study the biomechanics of hand movement to craft instruments that feel natural in a surgeon’s grip. Balanced weight and tactile control reduce fatigue, improving performance in lengthy procedures.

CNC Micron Machining

Our computer-numerical-controlled machining systems achieve micron-level tolerances — ensuring that every jaw, tip, and edge aligns with exact precision.

Thermal & Surface Treatments

Through vacuum heat treatment and passivation, we enhance hardness and corrosion resistance, extending the instrument’s lifespan while maintaining a sterile surface.

Functional Calibration

Every moving part — from scissors to needle holders — undergoes mechanical stress testing to validate smooth motion, consistent tension, and precise pressure response.

Laser Measurement & Vision Systems

Digital inspection ensures geometric consistency. Instruments are scanned and compared to 3D reference models to eliminate even the smallest imperfections.

Sterilization Endurance Testing

Tools are exposed to multiple autoclave cycles under extreme pressure and heat to confirm long-term sterilization safety.

Microscopic Edge Validation

Under magnification, edges are refined to perfection — ensuring clean incisions, minimal tissue trauma, and faster healing outcomes.

Traceability and Coding

Each instrument is laser-engraved with a unique identification code, guaranteeing full traceability across the manufacturing process.

Continuous Improvement Loop

Feedback from surgeons worldwide is analyzed to upgrade designs, materials, and finishes — making every new generation better than the last.

Innovation Meets Experience

At Dr. Spaul, innovation is guided by decades of surgical insight. We partner with global healthcare professionals to understand real-world challenges — translating their experience into technological evolution.

From AI-assisted inspection to robotic polishing lines, our production integrates automation with human precision — ensuring every tool that leaves our facility carries the signature of surgical perfection.

Global Standards, Local Craftsmanship

While we adhere to ISO, CE, and FDA-compliant protocols, our craftsmanship is deeply rooted in Sialkot’s heritage of excellence. This blend of tradition and technology gives Dr. Spaul instruments their unmatched reputation — combining handcrafted precision with scientific reliability.

Crafted with AISI 420, 440, and 316L stainless steel for maximum durability.

Micron-level CNC machining ensures flawless symmetry.

Instruments tested for cutting sharpness and spring balance.

Vacuum heat treatment provides structural consistency.

Autoclave simulation validates corrosion and sterilization safety.

Real-time laser inspection eliminates manufacturing variances.

Ergonomic designs reduce surgeon fatigue and enhance grip.

Quality audits at 7 critical stages ensure zero-defect production.

Collaboration with surgeons drives design innovation.

Every instrument is individually inspected before final packaging.

Every instrument we produce reflects our commitment to precision engineering, superior quality, and advancing surgical care worldwide.

09:00 Am - 11:00 Pm

© 2025 Dr. Spaul Enterprises. All rights reserved.